Mattress Industry: innovation and reduction

Mattress packaging evolution

Over the last years the trend towards reduction has been increasing. Companies have been moving towards reduction in any field, from energy consumption and environmental impact to production and transportation costs. The goal is to reduce waste and inefficiency and improve the production process.

The mattress industry has been showing the same trend. Companies have been facing new challenges to meet new needs. In particular, companies have been changing mattress packaging in order to improve transportation and reduce transportation costs.

How did it all begin?

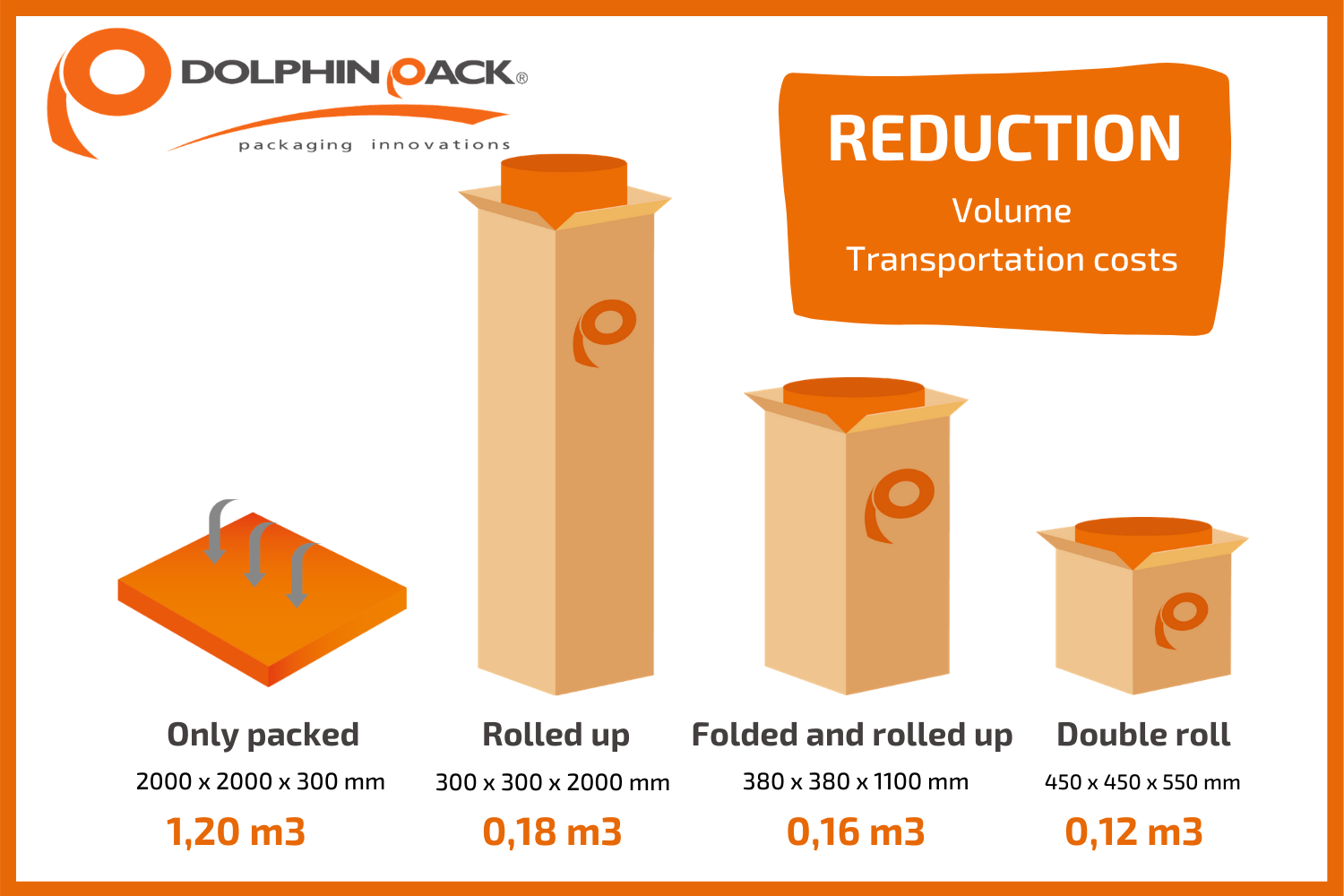

Mattresses are bulky and heavy products. Because of their size, only a few mattresses can be transported together and as a consequence, cost and time waste increase. In order to improve transportation, mattress volume must be reduced. The solution came in 1986, when Giuliano Magni filed a patent for the vacuum-packed mattress. His invention consisted of roll packing the mattress in order to remove air from the foam and reduce volume up to 90% without damaging the quality of the mattress. The invention of Magni revolutionized mattress packaging and improve transportation. By rolling up mattresses, the number of mattresses that can be shipped in one truck increased from 3/m3 to 13/m3 .Consequently, both transportation costs and CO2 emissions were reduced.

Just one click- the rise of the e-commerce

The invention of Magni became popular and widespread because of the advantages it offered. Over the following years manufacturers of packaging machines had developed new technical packaging solutions to roll pack mattresses and reduce their volume. Dolphin Pack launched Ander Roll, its own roll packaging machine in 2005. Then, in 2014-2015 the rise of e-commerce revolutionized again customer purchasing habits. At that time, an increasing number of mattress producers in the US started their online business by selling mattresses online only. The rise of e-commerce changed both customer purchasing habits and packaging of the product: mattress began to be folded, then roll packed, and put into boxes in order to be shipped to the final consumer via carriers. E-commerce trend rose sharply, therefore bricks and mortar companies changed their business model and started to sell online. A parallel trend was the increasing demand of packaging machine to reduce the mattress volume and meet the standards required by carriers for the shipment. Dolphin Pack launched ETESIAN, its fully automatic mattress packaging line. The machine is able to pack a wide range of mattresses with various dimensions. By adding a folding device, the volume of double mattresses can be reduced to fit a box with the following dimensions: 1100x450x450 mm.

Getting smaller and smaller

Customer purchasing habits and packaging needs have been changing over the last year mainly due to Covid-19 emergency. Accordingly, restrictions have been forcing us to rethink our habits in any field. As regards the mattress industry, online sales have increased. According to a survey conducted by the Better Sleep Council on the American market, 61% of interviewed had bought a new mattress online due to Covid-19 emergency.

New purchasing habits have been bringing with them new packaging needs, that is an extra mattress volume reduction. Mattresses must be more compact and smaller. Dolphin Pack developed ETESIAN DOUBLE, a solution to roll twice the mattress. In other words, ETESIAN DOUBLE is equipped with two roll pack machines, so that the mattress is rolled up twice and the final dimensions of the rolled-up mattress is reduced. Double roll packed mattresses fit in smaller boxes, e.g., 500x450x450 mm, according to the initial product dimensions. Thanks to ETESIAN DOUBLE both transportation costs and CO2 emissions are further reduced.

To sum up

As can be seen in the mattress industry, the trend towards reduction in product dimensions, production costs, and waste has been playing a pivotal role in the evolution of mattress packaging. The main goal has always been finding advantageous solutions both for companies, consumers, and the environment. The double roll, the latest packaging solution developed by Dolphin Pack reaches exactly this goal. On the one side, it helps improve transportation and reduce costs, on the other side it helps reduce CO2 emissions. Therefore, companies, final consumers, and the environment benefit from the double roll at the same time.

Find out more about Etesian Double

Join us at Interzum@home the international world’s leading fair for the furniture production and interior construction industry from 4th to 7th May and find out more about Etesian Double.

Request your free voucher and log in to the event platform